Introduction

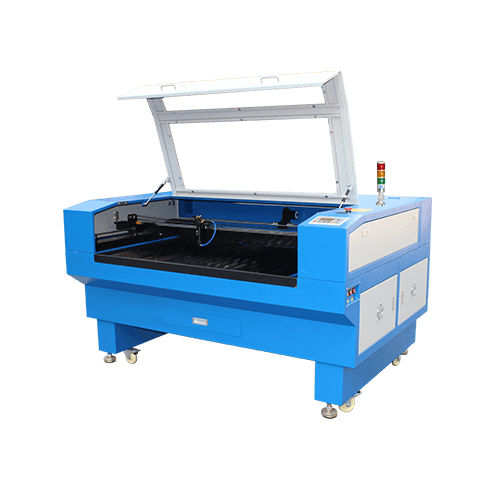

A laser cutter machine is the most effective tool for clean, fast, and precise cuts. It works perfectly on materials like acrylic, wood, leather, and paper, giving clean and high-quality results every time. Laser cutters are quicker and more precise than hand tools, providing consistent results with less effort every time. From signage and packaging to crafts and prototyping, laser technology is transforming industries.

What Is a Laser Cutter Machine and How Does It Work?

What Is It Made For?

A laser cutter machine uses a powerful beam of light to cut or engrave different materials. It’s great for both creative work and industrial tasks. A laser cutter is highly accurate, making it perfect for creating fine, detailed designs with ease. Since it is controlled by a computer, you can repeat the same design as many times as you need.

Main Parts of a Laser Cutter

A quality machine includes:

- Laser Tube (CO₂ type, e.g., Reci Laser Tubes)

- Mirror System to guide the laser

- CNC Controller for accurate motion

- Work Table to hold material

- Exhaust System for removing fumes

How It Works

The CO₂ gas inside the tube is charged with energy to produce a strong laser beam. This beam is aimed at the material through lenses, heating it until it melts, burns, or evaporates, leaving a clean and smooth edge.

Why Reci Laser Tubes Make a Real Difference

Powerful and Reliable

Reci Laser Tubes offer high power, consistent results, and long-lasting performance. Compared to basic tubes, Reci delivers better results with lower power usage. Redsail fits these tubes in many models.

Built for Longevity

Reci tubes can last up to 10,000 hours. They are built with high-quality glass and parts that stay strong even during heavy use.

Energy Efficient for High-Volume Use

Reci tubes are great for long jobs and big projects. They use less energy while still delivering powerful performance. That means better ROI for your business.

Laser Cutter vs Traditional Cutting Tools

Smooth, Splinter-Free Edges

Laser cutting offers clean edges without chips or splinters perfect for high-end projects or client work.

Exact Repeatability

Laser machines follow digital paths precisely. Whether cutting 10 or 10,000 units, the results are always accurate.

Minimal Maintenance

Manual tools wear down fast. Laser machines especially with Reci tubes—require minimal upkeep.

A Laser Cutter Machine is the Best Sticker Cutting Machine Alternative

Outperforms Traditional Sticker Cutters

Blade-based sticker cutting machines dull quickly. A laser cutter gives more precise results, works without touching the material, and keeps the work area clean.

No Dies or Limitations

Whether you’re cutting logos, QR codes, or labels, you won’t need extra dies or tools. Just upload your file and start cutting.

Supports All Sticker Materials

Paper, PET, vinyl, and more Redsail machines cut through them all with precision.

How to Choose the Right Laser Cutter Machine

Match to Your Material

Pick your machine based on the material you use most, like wood, acrylic, leather, or metal. Redsail offers models tailored for light and heavy-duty work.

Pick the Right Power

Lower wattage (40–80W) is perfect for engraving. Higher wattage (100–150W) handles thick materials. Reci Laser Tubes come in many power levels.

Look at Bed Size, Speed, and Software

Whether you’re a solo creator or running a factory, Redsail machines offer fast speeds, large beds, and easy-to-use software.

Laser Cutter Applications Across Industries

Signage and Display

Create clean-cut logos, letters, and lighted signs. Perfect for retail, offices, and events.

Custom Packaging and Prototyping

Laser cutters are ideal for creating custom packaging, such as box inserts and sample products with brand designs.

Crafts and Education

From school labs to home workshops, laser cutters allow hands-on learning and creative freedom.

Industrial Work

Cut gaskets, insulation, and metal sheets. High-powered Redsail models with Reci tubes handle large-volume, industrial jobs.

Simple Maintenance Tips for Long Life

Clean the Optics Weekly

Dusty lenses lower beam power. Use the right lens wipes to clean them and keep your machine working at its best.

Monitor Cooling Water

Regularly inspect the water cooling system and chiller in Reci tube machines to prevent overheating and ensure smooth operation. Avoid overheating to extend tube life.

Align Mirrors Regularly

Misaligned mirrors affect cut quality. Check the laser beam’s alignment each week and adjust it using the test tool if needed.

Clean the Exhaust System

Clear dust from the exhaust system monthly to keep airflow steady and remove smoke properly. This also protects your laser head.

A laser cutter machine is no longer just a luxury it’s a must-have tool for any business. Whether you’re replacing a sticker cutting machine, upgrading from manual methods, or expanding your production, Redsail offers powerful, long-lasting machines that keep you ahead. With Reci Laser Tubes inside, you get clean edges, fast cuts, and long-lasting durability. From design to delivery, Redsail is your partner in precision.